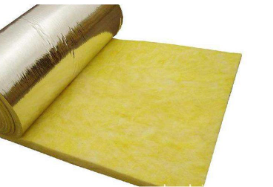

After the emergence of the 10 M Glass Wool Fiber Roll, it can meet many people's needs. This rationalization method exists, we need to make full use of it. The glass wool board is used in the fiber form after the glass is blown because the fiber in this way can achieve a different effect after the treatment, and this method solves the need well. Durability and insulation, the fiber's composition can be processed by centrifugal technology, and the resulting glass wool board gives people a different experience.

Because the 15 M Glass Wool Roll's own material is stable in its selection, it is more widely used. The half-body nature of many materials on the market is not good, and the manufactured products are definitely short-lived. So most of them are curious about the installation of the glass wool itself. Let's take a look at how the power behind it is installed.

Generally, the materials with superiority are more rigorous in installation. In the whole process, they are carried out from top to bottom. We carry out a certain staggering manner along the horizontal direction, and the installation is perpendicular from the corner of the wall. The entire material is on the staggered mounting plate. We remember that there is a vertical mounting width in the staggered places. We should see the glass wool boards intertwined. For the four corners, no other excessive docking is required. When cutting, it is necessary to carry out the whole piece. When it is pasted, it needs to be in the direction perpendicular to the wall surface. It is best to carry it in the state of heat preservation, so that the whole installation effect is complete. Therefore, for glass wool, it is necessary to have a more regular way to organize and install, so that there will be such a good feature on the market.

Copyright © Shi Jia Zhuang Bei Hua Mineralwool Board Co., Ltd. All Rights Reserved | Sitemap | Powered by